Swirling Dynamic CalcinerIntroduction

Swirling Dynamic CalcinerIntroduction

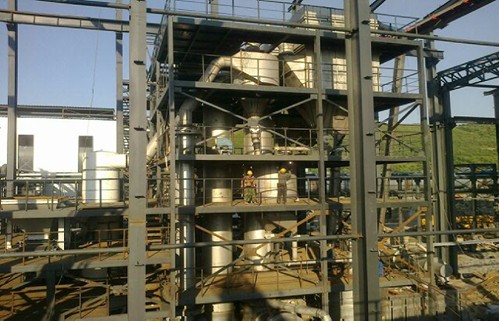

Swirling dynamic calciner is the first dynamic calcining device for powdery material in domestic successfully developed by our company in 1997,the calciner is composed of gas heater, gas and solider mixer, furnace body as well as gas and solid separated collector. The pre-calcining material is delivered to the furnace by the gas and solider mixer and moves with combination of the air heated by the air heater in the swirling state; after the completion of the calcination, it gets into the air and gas separator from the outlet of calciner; at last the separated solid and gas are respectively discharged from the discharge opening and air outlet opening.

Continuous operations, controllable temperature, smooth mixing of gas and solid as well as stable product quality.

Instant calcination, no over-burning, available for the manufacture of product with activities.

Closed system, no pollution, high recycle rate and civilized manufacturing.

Cooler and drier are equipped for tail gas to utilize the heat energy effectively.

Tail gas recovery processing system is equipped for the treatment and utilization of tail gas.

Air temperature in calciner: 500-1600°C

Granularity of material: < 60 meshes

Fuel: solid(coal), gas (coal gas, natural gas), liquid (diesel oil heavy oil )

Combustion mode: direct, indirect and internal and external combustions.

Swirling dynamic calciner is the first dynamic calcining device for powdery material in domestic successfully developed by our company in 1997, which has achieved the national patent.

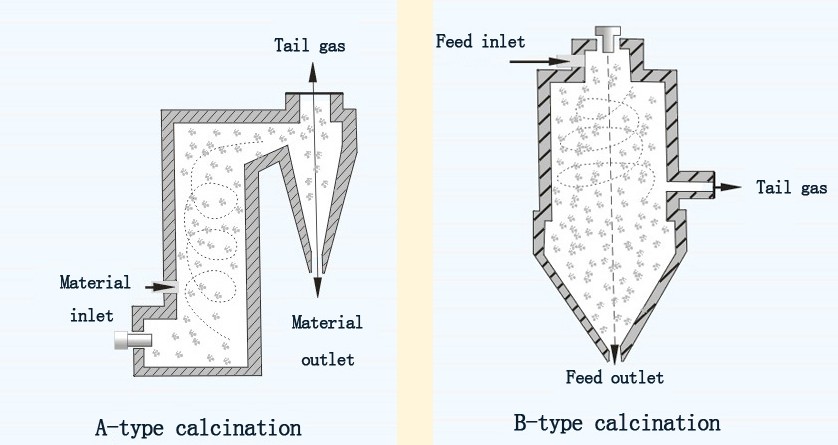

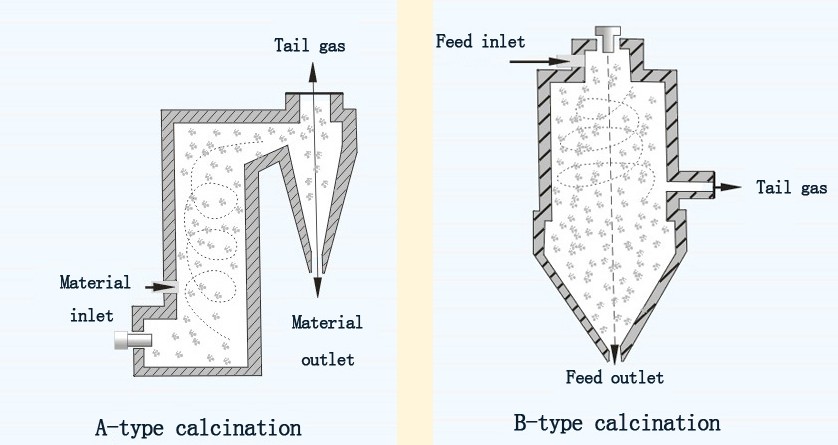

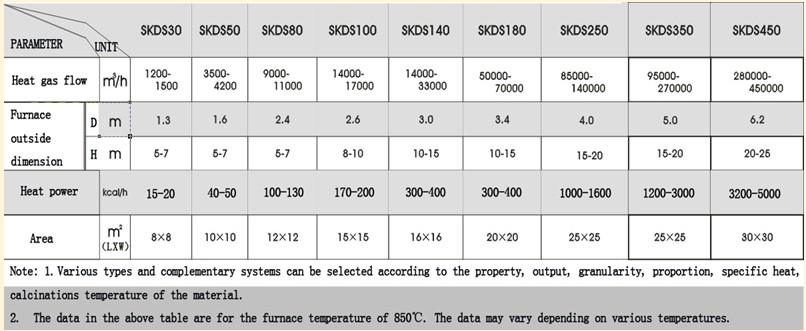

The different calcining process causes the various furnace types. Ensure the furnace and matching modes according to the calcining requirements of the different materials

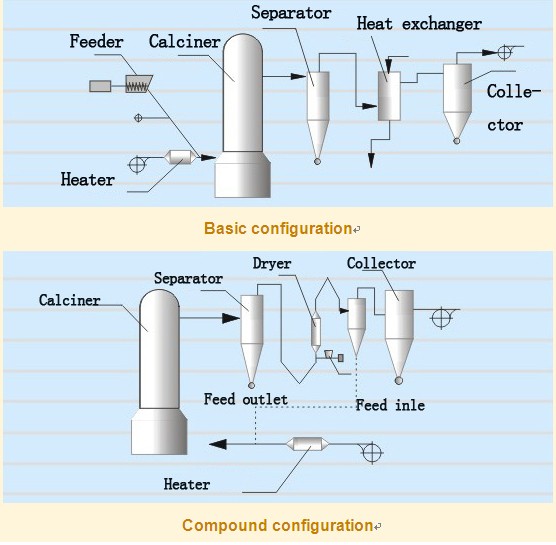

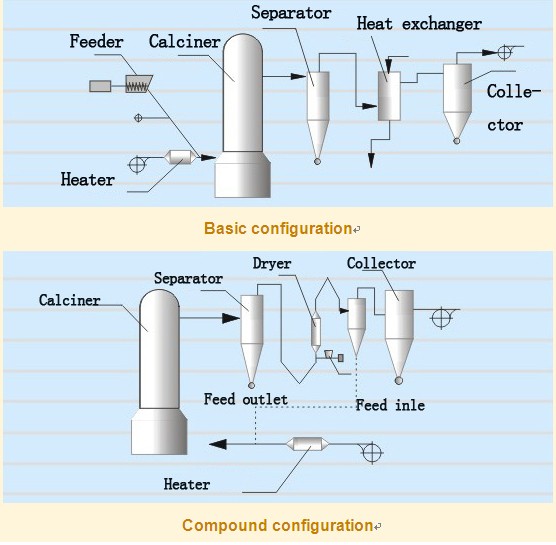

Usually air inducing device is provided; the system is in micro-negative pressure; heat resource is achieved by the direct or indirect way; tail gas is separated by the swirling air; air cooled; air purification and product recovery by packaging, static electricity or scrubbing.

To utilize the tail gas, a drying device is equipped at the tail gas calcining part, which can pre-heat and dehydrate the pre-calcining material to get the exhausting temperature of tail gas lower and use the energy effectively.

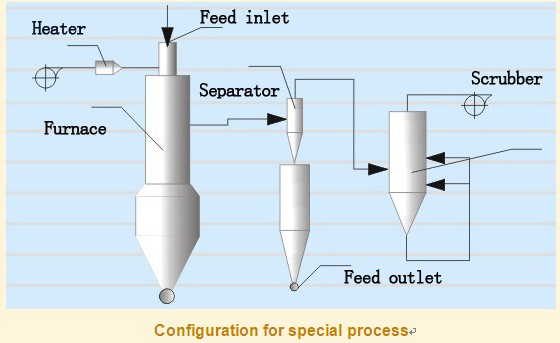

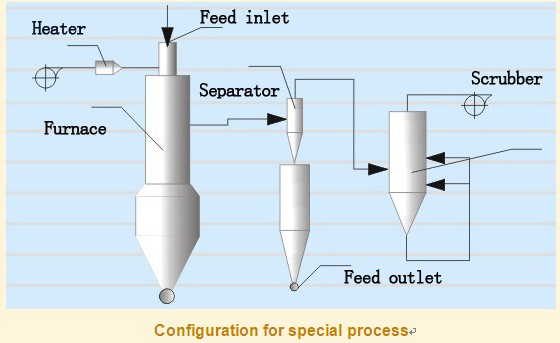

For the material with special process calcining requirements such as prolonging the thermal insulating time, recovering the calcinated gas and protecting the inert air, the matching configuration should be provided to meet the process requirements.

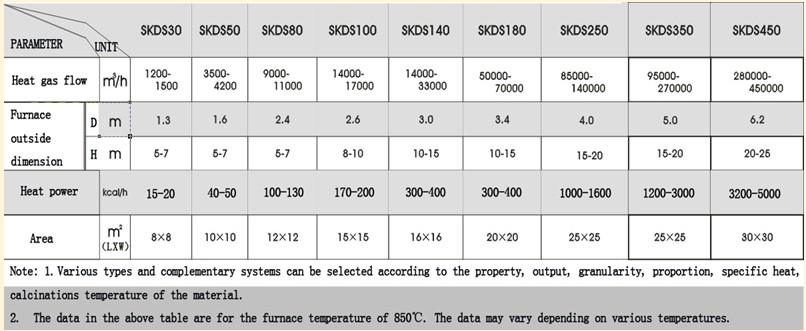

We provide furnaces of different specifications, design, manufacturing and on-site installation, and customized design for special calcining process furnaces.

We provide testing equipment for industrial furnaces to meet testing demands for various materials.

Our Mission/ Create a national brandCore Value/ Focus, Active, Diligent, Extreme

Our Mission/ Create a national brandCore Value/ Focus, Active, Diligent, Extreme Our Mission/ Create a national brandCore Value/ Focus, Active, Diligent, Extreme

Our Mission/ Create a national brandCore Value/ Focus, Active, Diligent, Extreme

Chinese

Chinese