The working principle of calcium carbide slag calcined into calcium oxide

The working principle of calcium carbide slag calcined into calcium oxide

1. The working principle of the calcination system

The main component of carbide slag is calcium hydroxide. The particles of carbide slag are relatively fine, and the surface water content is generally 25% to 45%. After removing the surface water of carbide slag, it is heated. Decomposes into calcium oxide.

1. Stead carbide slag calcination process:

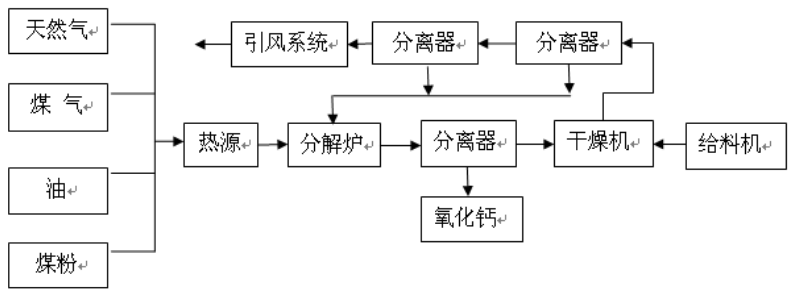

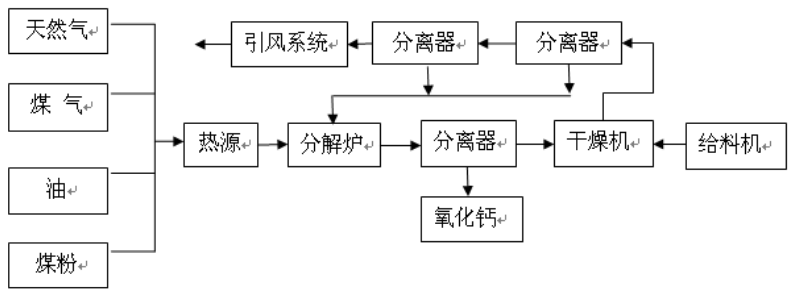

In view of the physical properties of carbide slag, our company has developed and designed a Sder calciner system for drying and calcining carbide slag. The process diagram is as follows:

According to the above process:

The calcium carbide slag is sent to the dryer by the feeder, and the carbide slag is dried by using the exhaust gas of the decomposition furnace to enter the dryer. The dry powder is sent into the calcining decomposition furnace, and the hot flue gas formed by burning natural gas, gas, oil or coal powder enters the decomposition furnace, and the high temperature flue gas is mixed with the powder calcium hydroxide (calcium carbide slag) entering the decomposition furnace. , rapid heat transfer, flow, calcium hydroxide is converted into calcium oxide in a few seconds, and the fired calcium oxide is separated by a separator and transported to a storage device for cooling and storage.

2. The characteristics of the calcination process of Sid carbide slag

The Sder decomposition furnace used in this process is suitable for the rapid decomposition of powdery materials. The decomposition furnace system has the following characteristics:

(1) The material is decomposed in a short time, and the fired calcium oxide has high activity.

(2) During the operation of the system, the calcium carbide slag is dried, decomposed and dispersed at one time, and the secondary pulverization process is not required.

(3) Compared with traditional calcining equipment, it can save energy by more than 30-50%.

(4) The system is operated under negative pressure, and there is no dust overflow, which meets the requirements of environmental protection.

(5) The system occupies a small area, requires less labor, and has a high degree of automation.

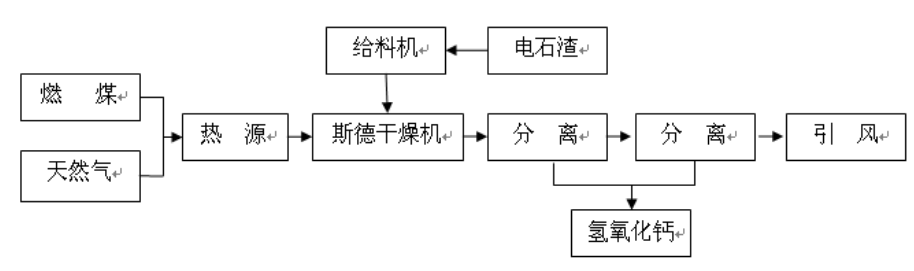

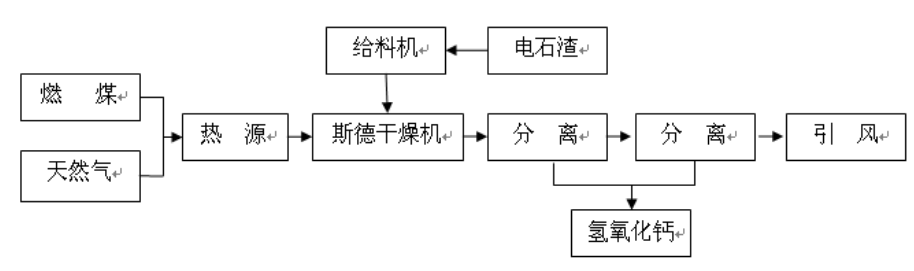

2. Introduction of Sidde carbide slag drying system

Carbide slag drying principle:

The complete set of special equipment for drying calcium carbide slag developed by our company has been successfully used in the industrial production of calcium carbide slag drying in Gansu, Xinjiang and other places. The process block diagram of the drying system is as follows:

The drying system has the function of dispersing and dispersing while drying, and the dried calcium hydroxide particles are uniform and have good fluidity. System energy saving, negative pressure operation, single set production capacity: under different water content conditions, the annual output can reach 100,000-300,000 tons.

Our Mission/ Create a national brandCore Value/ Focus, Active, Diligent, Extreme

Our Mission/ Create a national brandCore Value/ Focus, Active, Diligent, Extreme Our Mission/ Create a national brandCore Value/ Focus, Active, Diligent, Extreme

Our Mission/ Create a national brandCore Value/ Focus, Active, Diligent, Extreme

Chinese

Chinese