Working Principle

Working Principle

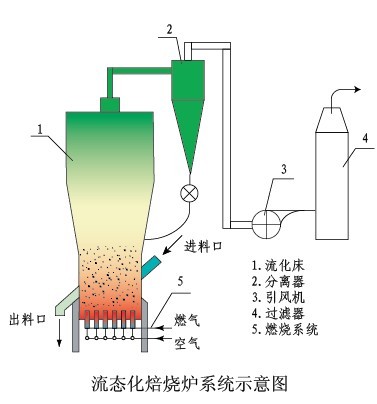

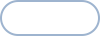

The fluidized fluidized bed is composed of a closed box, mainly composed of a fluidized chamber, a fluidized orifice, a high-temperature air chamber, and a base. The materials of the fluidized chamber and each part are selected according to different temperatures and physical properties of the calcined material. After the material enters the fluidization chamber, it is moved by high-temperature air, and the material produces a fluidization effect. After continuous fluidization, it is discharged from the discharge port after the material calcination process requirements are completed.

Adapt To The Material

Adapt To The Material

Pyrite desulfurization roasting, phosphate roasting, coal activation, mineral roasting

Carbide metal oxidation, high temperature roasting and decomposition of chemical products.

Municipal industrial waste incineration.

Schematic Diagram Of Fluidized Roasting

Schematic Diagram Of Fluidized Roasting

Performance Characteristics

Performance Characteristics

Intermittent or continuous operation, the material is heated uniformly.

Material temperature control is accurate

The system is closed and pollution-free

Maximum operating temperature 1000℃

The calcining hot air is direct or indirect heat exchange air, and the indirect heat exchange air temperature is >750℃.

Fuel is gas, liquid or coal-fired

Our Mission/ Create a national brandCore Value/ Focus, Active, Diligent, Extreme

Our Mission/ Create a national brandCore Value/ Focus, Active, Diligent, Extreme Our Mission/ Create a national brandCore Value/ Focus, Active, Diligent, Extreme

Our Mission/ Create a national brandCore Value/ Focus, Active, Diligent, Extreme

Chinese

Chinese