Technology features

Technology features

High rotation speed,fine fog drop,high drying speed,low cost,stable product quality.

Very high drying speed:after be atomized by high speed centrifugal,the surface of liquid materials will be enlarged enormously,only tens of seconds are needed to finish drying.

tepless speed change is adopted,most suitable rotate speed can be selected,and the granularity size of dried products can be controlled.

Product granularities are close to globularity,equal granule,with good fluidity and dissolution ability.Product with high purity and good quality.

Low atomizing disk erosion speed

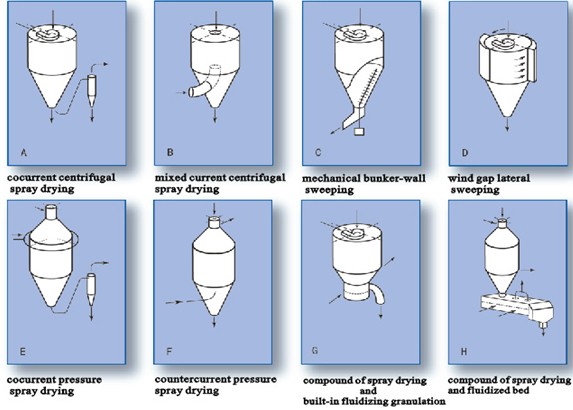

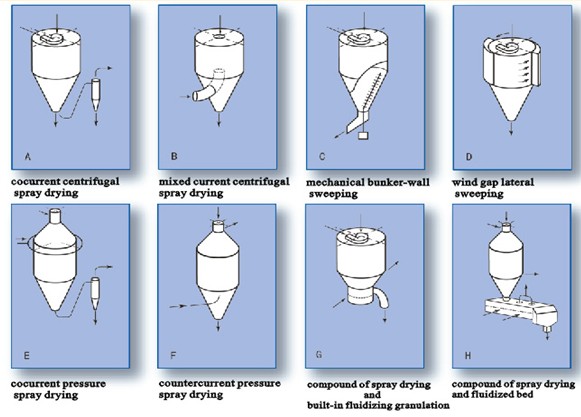

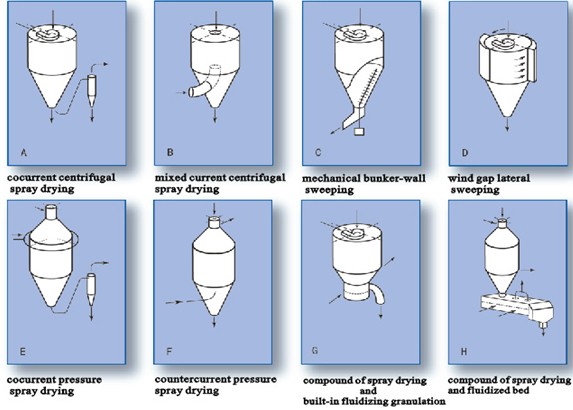

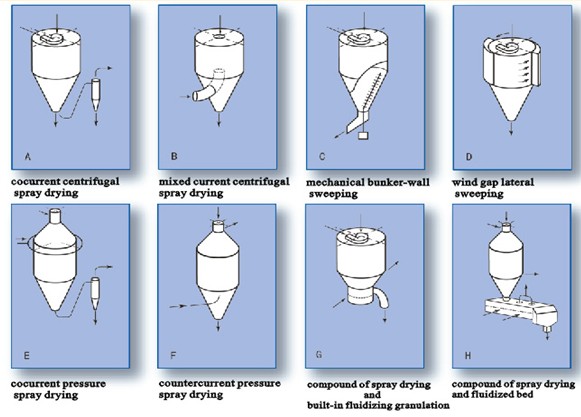

Centrifugal spray and pressure apray drying room show various structure forms,and choose different structures according to the physical property of materials to apply to the drying of different materials.

Typical common models are as below:

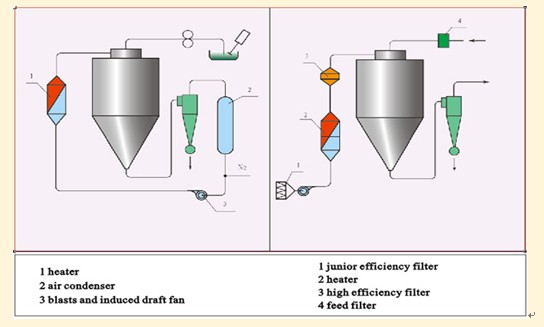

The drying of special materials such as flammability,explosive as well as medicine,food drying under the environment of asepsis,may adopt matching methods as below.

The basic choices of spray system

The basic choices of spray system

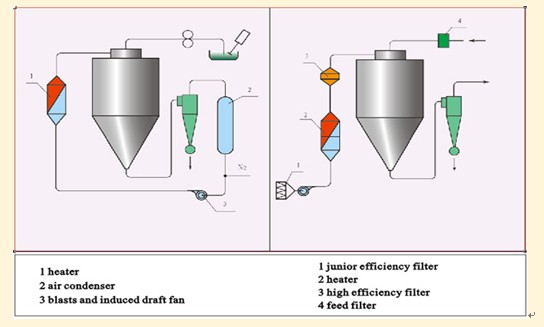

The spray drying system mainly consists of drying room(tower),liquid atomize system,air heater,tail wind retriever.According to materialsdrying physical property to choose tower structure,size,centrifugal and pressure atomize method,as well as air heating and tail wind retrieve method.Suitable system choices and configuration can make equipment run continuously,reduce operation cost,common system configuration method is as drawing.

Pressure spray drier

Pressure spray drier

Pressure spray drier is a kind of gas and liquid counter current or concurrent two types of drying device.It adopts high pressure pump or high pressure blast to atomize liquid materials,and make that move counter currently with hot air,then produce granularity products in short time.

Technology performance features

Technology performance features

Simple spray nozzle ,low atomization power,convenient operation and maintenance.

Suitable for low viscosity liquid materials drying .

It can produce big size granular products to meet the demand of granulation process.。

Its more adaptable to heat-sensitive materials.

Centrifugal spray and pressure spray drying room show various structure forms,and choose different structures according to the physical property of materials to apply to the drying of different materials.

Typical common models are as below:

In the spray dryer liquid materials are sprayed into fog under centrifugal force and pressure,and atomized into fog drops in a short time ,therefore they contact with hot air on larger surface and are dried into powder.Spray drying technology can be used for flowed liquid drying such as emulsion,suspensoid ,paste,glue type liquid etc.

Our Mission/ Create a national brandCore Value/ Focus, Active, Diligent, Extreme

Our Mission/ Create a national brandCore Value/ Focus, Active, Diligent, Extreme Our Mission/ Create a national brandCore Value/ Focus, Active, Diligent, Extreme

Our Mission/ Create a national brandCore Value/ Focus, Active, Diligent, Extreme

Chinese

Chinese