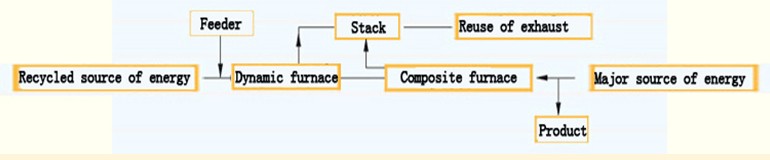

Composite calcination process involves the following processes

Composite calcination process involves the following processes

Rapidly raising the temperature of the materials which is to be burnt in dynamic calciner, then putting these materials into composite furnace after their reaching the temperature required by the technique, extracting the burnt materials through exit after elevation of temperature and constant preservation of temperature.

Calcination temperature and time can be controlled.

Direct heating through internal combustion is adopted, with high heat efficiency and no pollution.

Calcination temperature range is among 600-1300℃.

Output capability is among 500-5000㎏/h.

Process diagram

Process diagram

Calciner characterized by decomposition of magnesium chloride into the magnesia.

Calcination of the magnesium chloride into the magnesia through one-or-two steps

Calciner characterized by decomposition of cobaltous chloride and nickelous chloride into cobalt oxide and nickel oxide

Recycling of gas to obtain hydrochloric acid

Composite calcine furnace appropriate to kleit

Decarbonization and activated treatment of soil formed by coal and soft soil.

Calciner made by zinc oxide material

Used in calcination of nanometer zinc oxide, zinc oxide and active zinc oxide

Calciner made by boron magnesite and magnesite

Used in removing crystal water, making surface active

Composite calciner made by molybdenum ore concentrate

Used in calcination of molybdenum ore concentrate and

Our Mission/ Create a national brandCore Value/ Focus, Active, Diligent, Extreme

Our Mission/ Create a national brandCore Value/ Focus, Active, Diligent, Extreme Our Mission/ Create a national brandCore Value/ Focus, Active, Diligent, Extreme

Our Mission/ Create a national brandCore Value/ Focus, Active, Diligent, Extreme

Chinese

Chinese